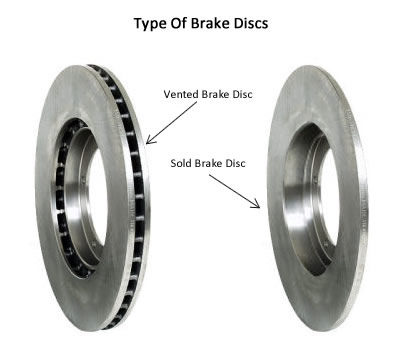

Do you know the difference between solid and vented rotors? If you're thinking this question is about the drill-pattern on the rotor surface, it's not. What this question is referring to is the inner structure of the friction surface.

A solid brake rotor is a single, solid disc. Vented rotors have two solid discs, divided in the middle by structures called vanes. Vanes add material to a rotor, increasing the rotors thermal capacity and creating additional pathways where heat can escape.

It's most common to see vented rotors on the front brake system of automobiles and solid rotors on the rear brake system. The front brakes do more work as most of the vehicle's weight is transferred to the front when slowing down. Photo Source: dcperformance.co.uk

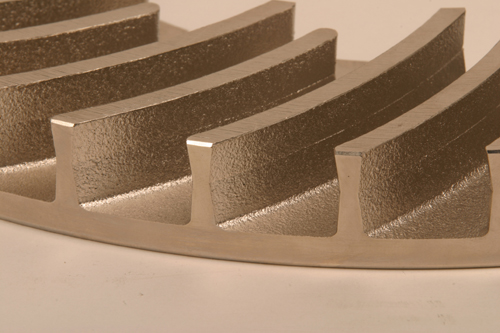

ROTOR VANE EXAMPLES

Straight, Radial or Non-Curved Rotor Vanes – this type of vane design in a brake rotor is the most popular and widely used for general brake applications, such as every day, street driving. These brake rotors are light in weight because they require less material (compared to curved rotors), but have better cooling capabilities compared to solid rotors. When compared to other rotor vane designs however, there are other designs that have better cooling and performance capability. Other straight-vane designs include:

Straight, Radial or Non-Curved Rotor Vanes – this type of vane design in a brake rotor is the most popular and widely used for general brake applications, such as every day, street driving. These brake rotors are light in weight because they require less material (compared to curved rotors), but have better cooling capabilities compared to solid rotors. When compared to other rotor vane designs however, there are other designs that have better cooling and performance capability. Other straight-vane designs include:

Photo Source: socalevo.net

- The Pillar Vane – this vane design uses a patterned arrangement of “dots” or lines for the vanes, casted between the two friction plates.

- The Variable Vane – this vane design is similar to the straight vane but comes with a variation in vane pattern and a less predictable pattern of arrangement.

All of the designs mentioned above are “non-directional,” meaning these designs are not side specific. A pair of drilled and slotted, straight vane rotors can be installed on the right or left side of a vehicle—performance is not very much affected by the direction of the slots/cross drills. People often confuse “directional” and “non-directional” with the drill pattern of the rotors, but these terms are meant primarily for the vane structure. With this being said, brake rotors are typically directional and side specific when the vanes are curved.

Curved Rotor Vanes – this type of rotor vane is predominantly used for motorsport or racing applications and is most commonly used by race car professionals. These rotors are typically heavier than straight vane rotors because more material is used for the curved vanes. Since there is more material, curved vanes have better thermal capacity and are able to withstand heavy brake applications better. Some other curved vane designs are the variable curved vane or convergent vane rotors.

All brake rotor manufacturers have their opinion about what is best for performance and how brake rotors should be installed. Our advice is that vane direction is more important when it comes to performance compared to drill pattern direction.  Photo Source: socalevo.net

Photo Source: socalevo.net

NOTE: Different car manufacturers have left and right side specific rotors with the vane direction going opposite directions when installed, others have them going the same direction. We suggest you follow what the vehicle manufacturer recommends.

used car inspection

posted on Jul 18, 2012 9:34:21 AM