* Source: forums.bimmerforums.com

* Source: forums.bimmerforums.com

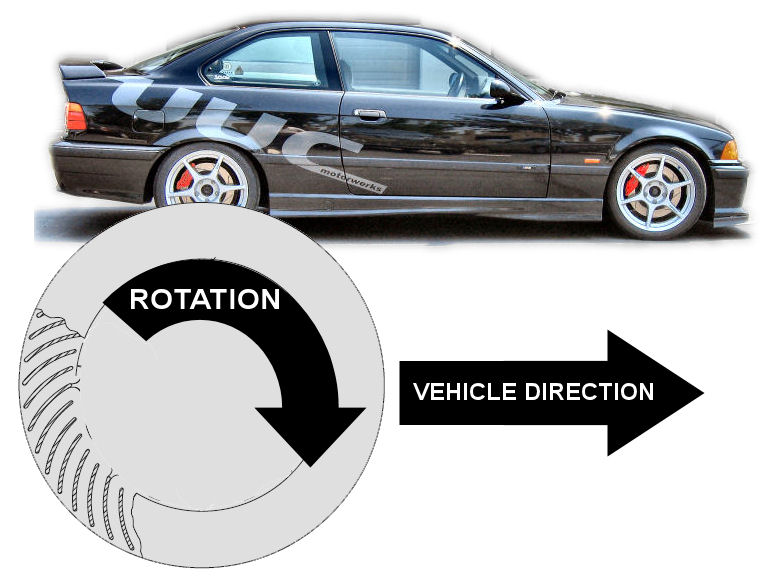

Installation of a pair or full set of performance brake rotors is pretty simple if you understand the science behind how theyfunction. Installing a set of brake rotors with a curved set of cooling veins is a bit different than installing a set with straight veins, so this is something to be aware of for each unique install.

Other than determining brake rotor orientation, based upon design variance, basic quality control must be performed to ensure proper quantitative variances are kept. Just as you would check over rotor tolerance numbers when changing out brake pads, new rotors should be scrutinized as well before install. Excessive run out and/or surface defects are what the installer is trying to identify, and each individual manufacturerproduces lit...

Read More