* Source: forums.bimmerforums.com

* Source: forums.bimmerforums.com

Installation of a pair or full set of performance brake rotors is pretty simple if you understand the science behind how theyfunction. Installing a set of brake rotors with a curved set of cooling veins is a bit different than installing a set with straight veins, so this is something to be aware of for each unique install.

Other than determining brake rotor orientation, based upon design variance, basic quality control must be performed to ensure proper quantitative variances are kept. Just as you would check over rotor tolerance numbers when changing out brake pads, new rotors should be scrutinized as well before install. Excessive run out and/or surface defects are what the installer is trying to identify, and each individual manufacturerproduces literature to help with this identification process.

Back to brake rotor vein design....

Most stock brake rotors employ a straight vein rotor design, whether columnar or staggered, because these rotor designs are cheap to produce. Cooling may not be superior to a curved vein design, but can do an adequate job givena non-abusive braking style. When installing this variety of brake rotor, there isn’t any way to get it wrong; orientation does not matter.

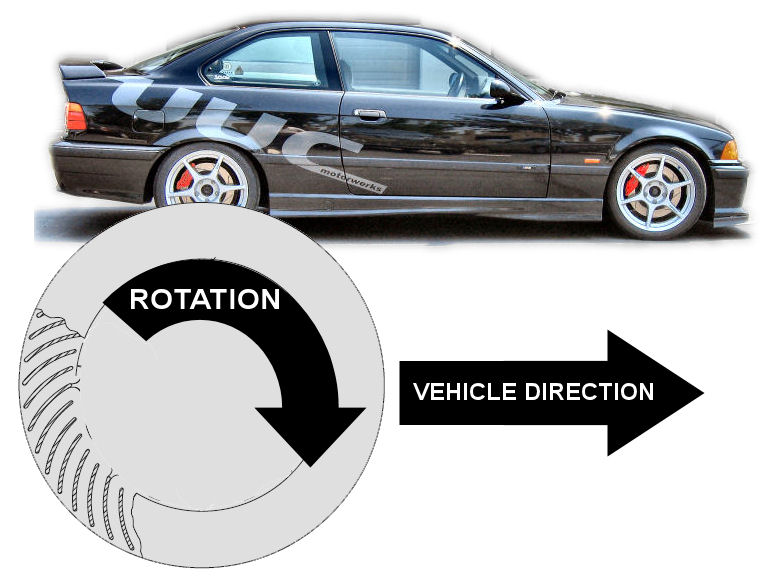

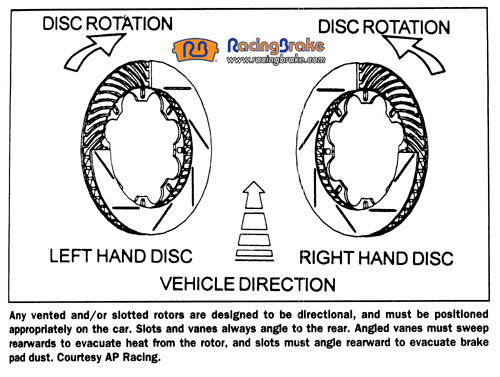

Curved or directional brake vein rotor designs, on the other hand, are very much orientation sensitive; they don't call them ‘directional’ for nothing. A curved vein brake rotor made for the right side of the vehicle must be installed on the right side of the vehicle,it’s as simple as that.

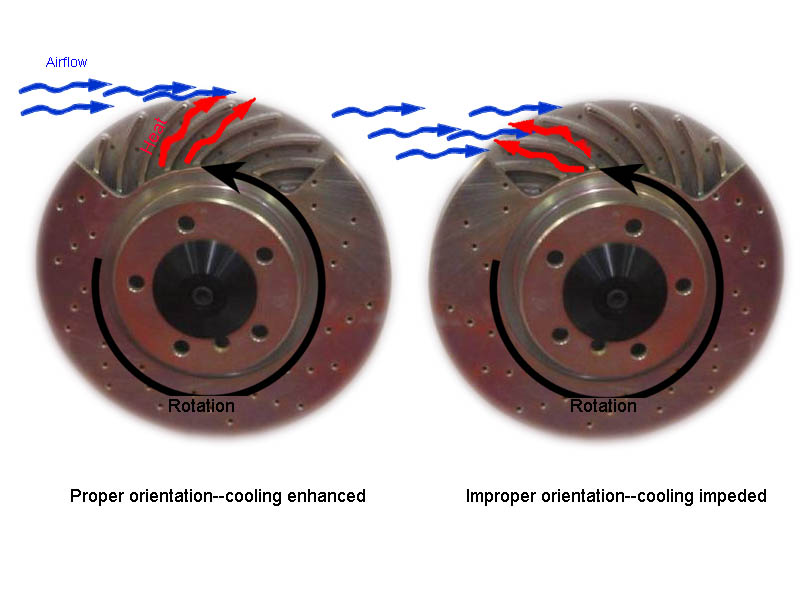

Many people make the mistake of installing a right wheel designated brake rotor on to the left side of the vehicle,and vice versa, because they do not understand how these curved vein rotors work in theory. Theythink thatthese brake rotor veins are supposed to act like air scoops to cool the brake rotor off, and this certainly is not the case. These curved veins are actually used to increase air circulation through the use of centrifugal force, and do so by creating a vacuum inside the brake rotor plate sandwich. Because of this naturally created vacuum, air isconstantly beingpulled past the brake rotor in question and cools the brake rotoras a result, through convection.

*Source: blog.blackdogspeedshop.com

You could actually think of a curved brake rotor design to work much like a fan or turbine in function. Because of this fact, if you were to install a curved brake rotor on backwards with a rotor made for the opposite side of the vehicle, then the curved veins would cease to function as designed. Actually, purchasing a set of curved vein rotors and installing them on backwards is very much counterproductive, so it is important to hire a qualified mechanic that is aware of these installation details.

Drilled and Slotted Curved Vein Rotor Design Installs

Inexperienced rotor installers often make the mistake of improperly installingcurved veined rotors with drilled designs, because the drill sites actually run in a backwards or opposite direction as the brake rotor veins in question.

Not all rotors have drill sites that run in the opposite direction of the curved veins either, so always check out rotor vein direction for yourself before making any assumptions. Slotted rotors often run opposite to the direction of the rotor veins as well, so employ the same determination strategy as listed for the drilled out variety before installing any slotted-curved vein rotor types.